SRIMENS is the leading reconditioning and retrofitment company in India.

SRIMENS is the leading reconditioning and retro fitment company in India. We provide turnkey Solution in the area of all types of CNC Machines, Servo and new machines. We have completed more than 150 CNC retro fitment / Reconditioning.

We have full-fledged reconditioning set up with 10T EOT crane.

Over the years SRIMENS has dynamically handled various projects in automation and machine tools. Through the dedication and passion for work, SRIMENS has proved self as a dependable partner. Since inception, We have grown to become diversified machine tool company offering complete solution To user and machine tool manufacturer. Our organization has vast experience in variety of machine tools and SPM building.

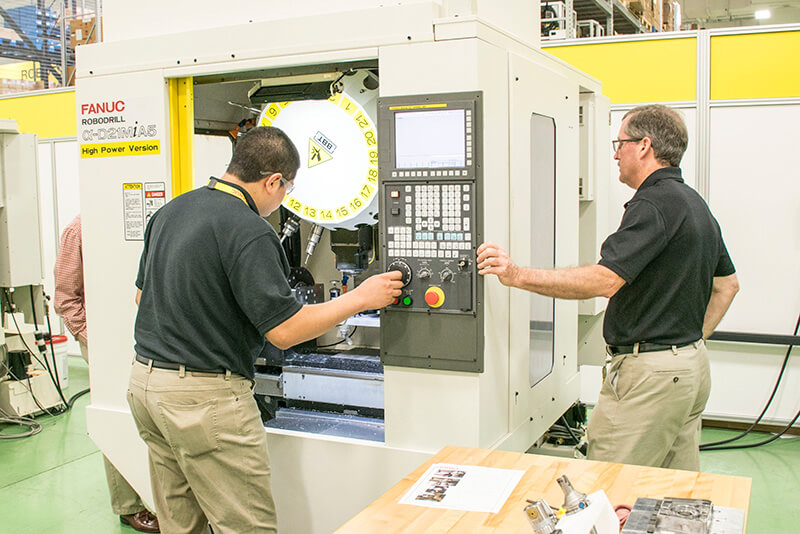

We do FANUC,SIEMENS ,MITHUBISHI system reconditioning with new machines.

CNC machine reconditioning is an essential process for manufacturers looking to extend the life and performance of their machinery. As CNC machines age, they may experience wear and tear that affects their precision and efficiency. Through reconditioning, these machines can be restored to their optimal operating condition, ensuring continued productivity and cost-effectiveness.

Engaging professional CNC repair services is essential for resolving mechanical and electronic issues. Regular maintenance extends machine lifespan and reduces unexpected downtime. Additionally, CNC retrofit solutions can modernize older machines, enhancing functionality and productivity. Overall, investing in CNC machine reconditioning helps manufacturers remain competitive and optimize operations in a dynamic market.

Proactive CNC maintenance routines are essential for identifying potential issues early, reducing the risk of costly repairs and unexpected breakdowns. Scheduled inspections and timely interventions are crucial. Additionally, implementing advanced CNC retrofit solutions allows manufacturers to upgrade technology in existing machinery, enhancing performance and preserving assets. These strategies improve operational efficiency and promote a culture of continuous improvement, helping businesses remain competitive in a changing industry.

Prioritizing CNC repair services helps manufacturers address mechanical failures and improve equipment health through inspections and targeted repairs. Regular maintenance can identify minor issues before they lead to significant disruptions, protecting productivity. Additionally, combining these services with CNC retrofit solutions allows businesses to upgrade older systems with modern technology, enhancing operational performance and fostering innovation, which is essential for competitiveness.